Warrior Open Hole Well Logging System

The Warrior Well Logging System employs advanced software and widely available hardware to provide a cost-effective solution to well logging requirements for open and cased hole applications in SRO, LWD and memory operations.

Wide Range of Down Hole Tool Support

Scientific Data Systems supports the widest range of down hole tools from many manufacturers. Tools in current production and obsolete equipment are supported.

Generic (Tools Available from many manufacturers): Gamma Ray, CCL, Neutron, RA Tracer, Temperature, Pressure, Pulse tool type, Production logging, Noise, Gravel Pack, Multi-fingered Caliper (Max/Min)

Industrial Oil Field Tool manufacturers: Computalog / SIE, DSS, Hunting Titan, Canada Tech, Applied Electronics, Artex, GE Energy (Sondex), Guardian Global Technology Ltd, Panex; Micro Smart, Gearhart, Geotron JSC, Hotwell, Hunter Well Science, Cedar Bluff Group, Lee Specialties, Spartek, Probe, Western Atlas and Gowell.

Ease of Use with Graphical User Interface

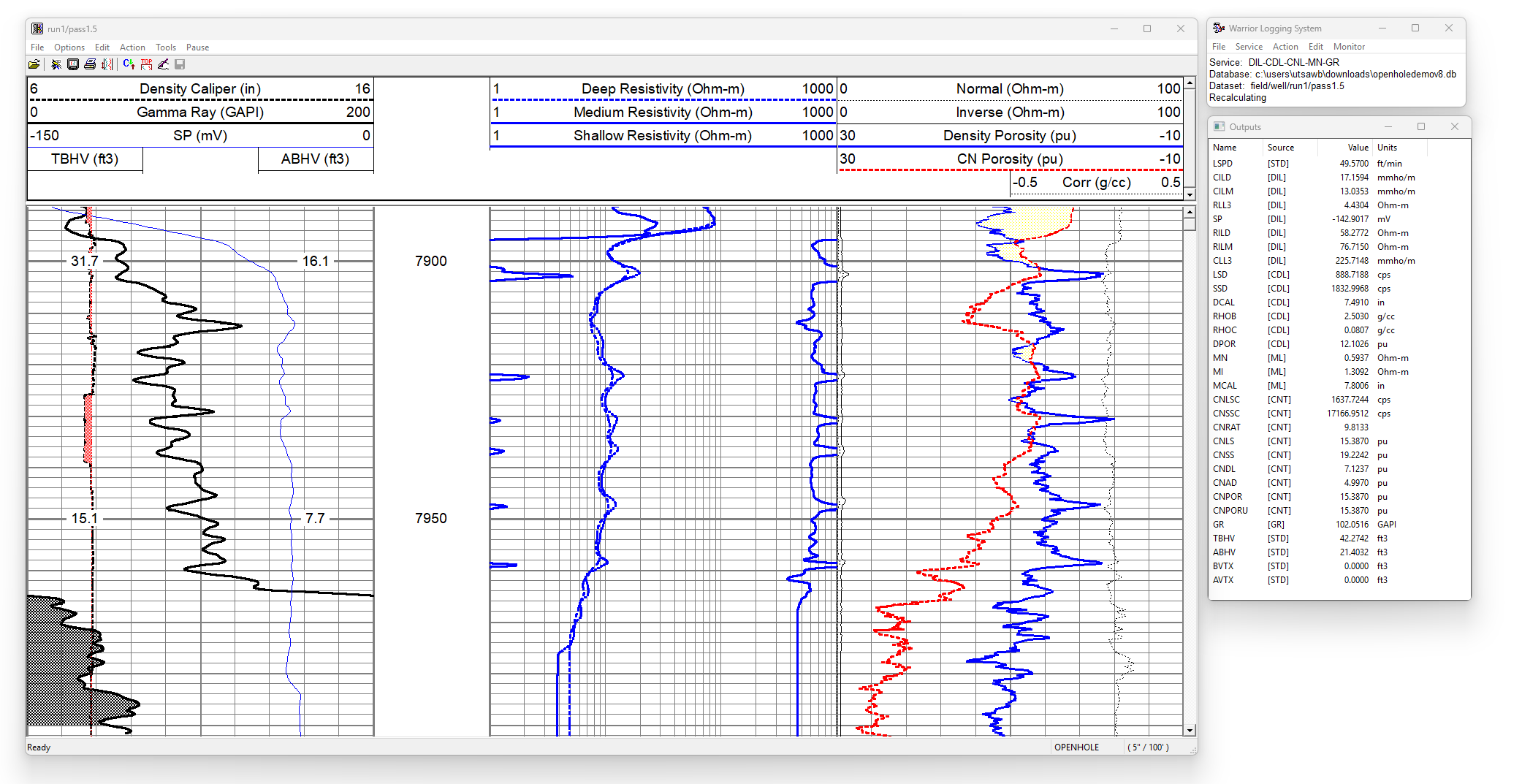

The system is easy to use and the interface conforms to the popular MS Windows standard. Data monitoring is available in windows, which may be resized and repositioned as the user wishes. A typical user screen with scrolling log display and data monitors is shown below.